In this National Rural Network EIP-AGRI guest blog, James Gaffey, Co-Director of the Circular Bioeconomy Research Group (CIRCBIO) at Shannon ABC in IT Tralee and coordinator of the Biorefinery Glas EIP-AGRI Project, small-scale grass biorefinery demonstration project provides us with an insightful overview of the bioeconomy, and its potential in terms of Ireland’s future economic and environmental wellbeing. He also explains how the Biorefinery Glas project is trying to understand and demonstrate how we can sustainably add value to Ireland’s most abundant resource, grass, through the new lens of the bioeconomy.

“Bioeconomy” has become a bit of a buzz word in recent times. It refers to the knowledge-based production and use of biological resources to provide products, processes and services in all economic sectors within the frame of a sustainable economic system. These biological resources, which form the building blocks of the bioeconomy are largely derived from our agriculture, forestry and marine sectors. They can be crop waste, vegetable waste, brash or seaweed, all coming with very distinct compositions and different potential for developing new biobased products. In the bioeconomy, seaweed, for example, can be converted into healthy nutritional products, cosmetics and energy, while forestry waste can be transformed into transport fuels and high value chemicals.

Through the EIP-AGRI Biorefinery Glas project, IT Tralee together with our partners UCD, GRASSA, Carbery and Barryroe have been exploring one of Ireland’s oldest resources, grass, through the new lens of the bioeconomy, to understand how we can sustainably add value to Ireland’s most abundant resource. Through this lens, grass can be a source of protein or amino acids, sugars (mono-, di-, poly- and oligosacchardies), fibres, organic acids, lipids and minerals, providing Ireland with a vast reservoir of potential.

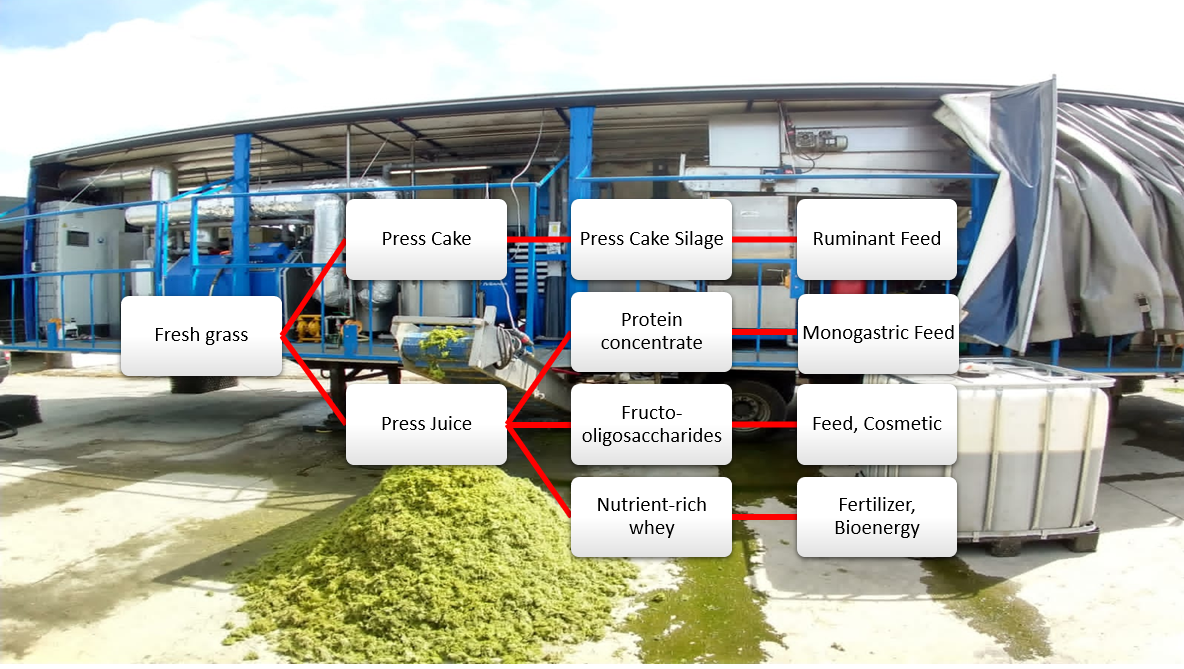

Through Biorefinery Glas, we have been demonstrating how a small-scale mobile biorefinery (essentially a factory for producing products and energy from biomass) can convert grass into different product streams for use in many different applications. In the first step, grass is pressed and crushed to separate some of the protein, minerals and sugars into a liquid, while part of the protein and nutrients remain bound to the grass fibres. We have been conducting feed trials with dairy cows at UCD’s Lyons Farm, and while this fibre is much lower in protein content compared with silage, there is essentially no difference in the volume and quality of milk produced. Overall a much higher proportion of the protein from the biorefinery fibre, ends up in the milk, with a much lower amount ending in excrement, compared with silage. This development can have a position impact on nitrogen related livestock emissions such as ammonia and nitrous oxide.

In addition, some preliminary results from our study shows that this feed may also be able to reduce rumen methane emissions by as much as 15%. With our fibre performing on a par with silage, it allows us to explore the potential of other additional valuable co-products we can extract from grass. In this regard we have been working to isolate and concentrate the remaining protein within our extracted grass liquid to develop a protein concentrate which is similar in composition to soybean meal, and this is currently being trialled as pig feed through the Barryroe Co-op.

Currently Ireland’s compound feed industry is heavily dependent on imported protein concentrates like soy which usually have a large carbon footprint and is, in some cases, linked with deforestation and biodiversity loss. Being able to use our Irish grassland more efficiently so that we can produce our own concentrates will make our livestock sector more sustainable and more resilient. Aside from better utilisation of protein, we also adapt the biorefinery approach to extract and purify high value compounds contained within the residual grass biorefinery stream. In our case, fructo-oligosaccharides, a prebiotic, which can help to enhance the growth of good bacteria in human and animal guts, are present in grass in relatively high volumes, and at Institute of Technology Tralee, we have been extracting and comparing these to on-the-market prebiotics, with very positive results.

Meanwhile adopting a circular and zero-waste approach we are evaluating the final liquid stream, the whey, as a nutrient-rich fertiliser which Carbery farmers have tested in field trials to good effect, and as a substrate for biogas production through anerobic digestion. Overall, the results of the product trials have been successful, and we are currently finalizing the economic analysis to understand the viability of the model in the current commercial environment. A major strength of our project is that it has enabled farmers, researchers and industry to work together to demonstrate this innovation. There has been a sharing of knowledge, not only from researchers to the farmers, but also from farmers to the researchers, where their practical knowledge of farm management, allows us to better understand the logistics and challenges of technology introduction. It has also shown, possibly for the first time, that a small-scale biorefinery can be implemented technically on farms, at small-scale with the participation of the farmers.

The EIP-AGRI Initiative, with its focus on bottom-up research has made this possible, and the Department of Agriculture, Food and the Marine (DAFM) has backed the project financially, clearly demonstrating their belief that the bioeconomy will shape the future of agriculture in Ireland. This support is also evident from the inclusion of the project within the Departments AgClimatise Roadmap document for decarbonizing the agri sector, a view shared by KPMG who highlighted the project within its 2020 agribusiness report focused on decarbonization of agriculture by 2050. Overall, it has been a great initiative to be a part of, and we look forward to our upcoming release of project results in early 2021. Overall the EIP-Agri experience has been a positive one for all those involved, and I would like to give special thanks to everyone who has made this project possible, in particular our participating farmers of the Carbery and Barryroe Co-ops, without whom this journey would not have been possible.

Author Biography

James Gaffey is Co-Director of the Circular Bioeconomy Research Group (CIRCBIO) at Shannon ABC in IT Tralee. James is Principal Investigator on the BBI JU ICT-BIOCHAIN and BIOSWITCH projects and currently coordinator of the EIP-Agri Biorefinery Glas, small-scale grass biorefinery demonstration project. He is academic collaborator in the SFI BiORBIC Research Centre and part of the SFI Farm Zero C team. Additional new projects include H2020s COOPID and AgroBridges. James is part of the core programme development team and lecturer on the Postgraduate Diploma in Bioeconomy with Business co-developed by IT Tralee, UCD and Teagasc. He has been a regular contributor to European-level studies into circular bioeconomy and is currently a member of the Expert Panel for the Impact Assessment of the European Partnership for a Circular Biobased Europe under the future Horizon Europe programme.

James Gaffey is Co-Director of the Circular Bioeconomy Research Group (CIRCBIO) at Shannon ABC in IT Tralee. James is Principal Investigator on the BBI JU ICT-BIOCHAIN and BIOSWITCH projects and currently coordinator of the EIP-Agri Biorefinery Glas, small-scale grass biorefinery demonstration project. He is academic collaborator in the SFI BiORBIC Research Centre and part of the SFI Farm Zero C team. Additional new projects include H2020s COOPID and AgroBridges. James is part of the core programme development team and lecturer on the Postgraduate Diploma in Bioeconomy with Business co-developed by IT Tralee, UCD and Teagasc. He has been a regular contributor to European-level studies into circular bioeconomy and is currently a member of the Expert Panel for the Impact Assessment of the European Partnership for a Circular Biobased Europe under the future Horizon Europe programme.

James joined IT Tralee in 2016, working as biorefinery specialist on the EU Horizon 2020 AgriForValor Project. Prior to this, James worked in the biorefinery industry since 2009 with Sustainable Biopolymers, Cellulac Ltd and the Technology Centre for Biorefining and Bioenergy (NUI Galway) and through projects including Bio-Eire, Future European League for Microalgal Energy (FUEL4ME) and Sustainable Polymers from Algae Sugars and Hydrocarbons (SPLASH).

Biorefinery Glas website: https://biorefineryglas.eu/

Biorefinery Glas Twitter: @BiorefineryGlas